Andonstar-2MP-USB-Digital-Microscope-Video-Camera-Repair-PCB

Welcome to Weather-Above

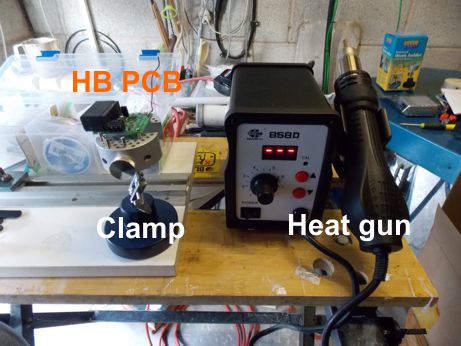

Now and again I come across a one wire sensor module that has become faulty. The data no longer display correct on the one wire network software, to repair the modules can be quite difficult as most of the components are surface mounted . I have tried using standard soldering iron to remove surface mounted components you just cannot get all the pins hot at the same time, and it's very easy to damage the printed circuit board. I decided to purchase a hot air rework station, this consists of a control unit which adjusts the temperature and the fan speed, it is very easy to use.

You can pick up a hot air rework station from approximately £20 from eBay. This is one of the best tools I've ever purchased.

I

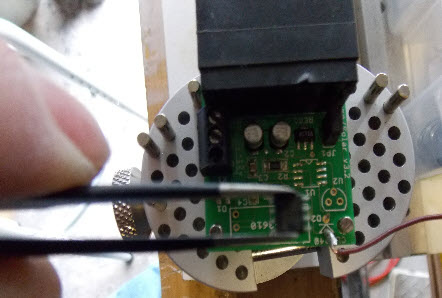

I would recommend also getting a small helping hands tool, these come in all different sizes and consists of some kind of clamping system to hold your circuit board while you are working on them. Some of these helping hands consists of crocodile clips, the clamp I am using has an adjustable jaw, in the top of the vice are lots of holes which enables you to put in round stainless steel pegs to help with holding different objects. You can see I've used two stainless steel pins which are located in the circuit board mounting holes and one either side of the RJ 45 sockets, then I adjust the jaw clamp to grip the circuit board in place. This Small vice Is a little bit more expensive but it is well worth the investment as it is made to last, I purchased mine from a local craft store.

The next stage

The hot air gun can use different types of nozzles, there are three nozzles in this kit .I used one of the smallest nozzles, you can purchase a nozzle that has been designed to remove ICs they have two metal strips which allow the hot air to blow either side on the pins, as I'm only removing this damaged IC it didn't matter if I overheated the chip but would recommend a dedicated nozzle if you are going to re-solder the ICs in place .Please see fig h4 image these nozzles cost approximately £6 from eBay.

Set the temperature on the control unit to approximately 340° and have the airflow medium, when you remove the hot air gun from the holder it will automatically start to increase its temperature and you will hear a small fan running as soon as it reaches the temperature you set. Take the hot air gun and position the nozzle over the IC chip wait for about 30 seconds then use a pair of tweezers to gently pull off the damaged IC

use a flux pen to go over the solder pads on the circuit board then gently reuse the heat gun over this area, this will allow the solder to flow flat then it's ready for the replacement chip.

fig h4

Repairing a hobby board module

To replace the IC apply some flux to the pads on the circuit board also apply some flux on the bottom of the new IC chip, you can use solder paste, I purchased this from eBay. There may be enough solder on the pads if so just place the new IC on the circuit board then gently heat using your heat gun, be careful not to move the IC during soldering. soon as the solder starts to melt remove the heat gun

If there is not enough solder on the pads I recommend using solder paste

which you apply a small dab onto the printed circuit board pads then place your IC in position wait a few minutes this will allow the IC to stick

then use your heat gun to solder all the connections.

My favourite method is using a really fine pointed soldering iron tip use a flux pen to coat the surface of the circuit board pads then use tweezers to hold the new IC and use the flux pen to coat the pins. Next position the IC on the circuit board make sure it is aligned properly then apply a small amount to solder the tip of the soldering iron then just touch one of the small pads and the solder will run to the IC pad

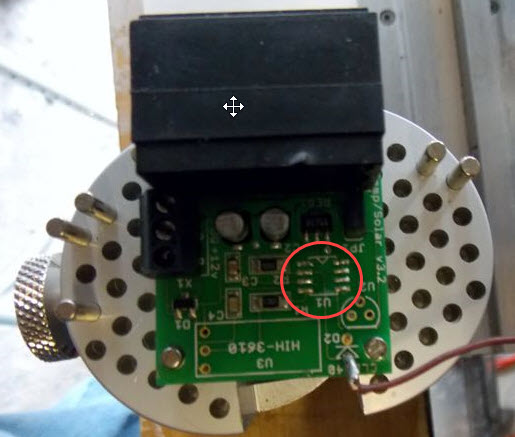

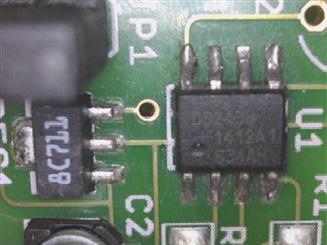

at this stage you can check your alignment and adjust as you've only soldered one pen, then repeat on all the other pins. If for any reason you get too much solder on the pins and they joined together don't panic take your soldering iron tip wipe any excess solder off it then simply drag the tip down the joined pins and eventually the solder will just run away onto the solder pads. I use another tool to inspect the soldering joints it's a USB digital microscope you simply plug into your USB port and place the circuit board underneath the camera focus and zoom in and take a picture. USB digital microscopes are not expensive great for Christmas presents birthday presents for anyone who has hobby electronics will find this tool very useful.

The new replacement IC chip viewed on the USB digital microscope

For more about how I use the USB microscope and software please click on the link at the top of this page